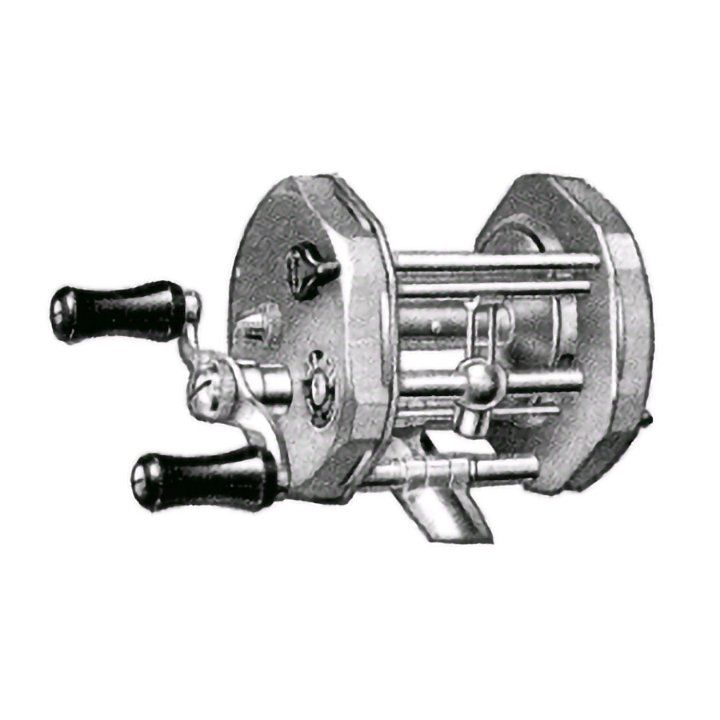

THE GILDEX

Level Wind, Casting and General Spinning Reel

A distinctive example of British light engineering; strongly built with some eighty precision-machined components comprising a unit that, with normal care and attention, will give many years of trouble-free service.

Exposed parts are treated to withstand corrosion, but your Gildex should have reasonable attention, as a routine, after use.

Features include:

- Sound reliable construction

- Superbly finished in Gunmetal and Bronze Polychromatic and Chromium Plate.

- Rapid Line-recovery by 4 to 1 winding ratio.

- Even distribution of line by Gildex infallible Level Wind Mechanism.

- Universal Hinged Rod Anchor or Reel Seat, improving adaptability to the various types of rod-fittings and folding inwards for convenience in packing.

- Lever-operated specially-treated steel Checkwork fitted in a convenient position for instant application.

- Adjustable sensitive Drag to prevent over-running.

- Ample line capacity.

- Free-running Drum on pivotal bearings.

- Every GILDEX is made of fine materials; is assembled with great care; and is unconditionally guaranteed free of defects in either materials or workmanship.

1959 Retail Price*: £9 9s.

THE GILDEX NO.2

Similar to the GILDEX but two ounces lighter and with covered viewing-apertures for simplified oiling. Line Capacity as Gildex.

1959 Retail Price*: £8 12s 6d

THE GILDEX JUNIOR

Similar to the GILDEX No. 2 but without the level-wind mechanism.

1959 Retail Price*: £6 6s.

*All prices are exclusive of Purchase Tax which is equal to one sixth of the price which must be added

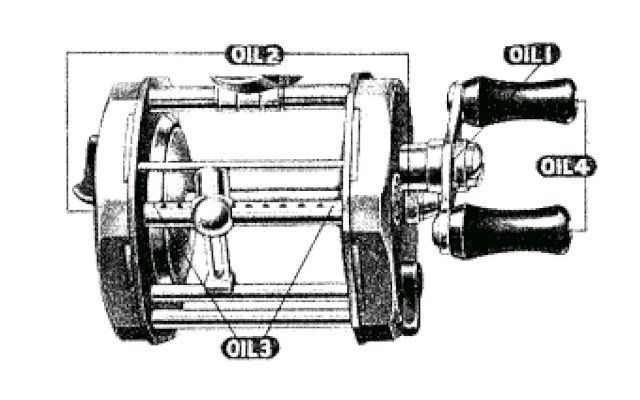

LUBRICATING & CARE OF YOUR GILDEX

Apart from giving the reel a thorough oiling in the dismantled state, the reel should be well oiled at essential points each time before use.

- Driving Gear Bearing by removal and replacement of handle plate retaining screw.

- Pivotal Bearings by revolving oil hole covers until holes are exposed. Re-cover after oiling.

- Cross Thread Level Wind Shaft at both ends and along surface. (This should not be neglected).

- Handle Pivot Bearings.

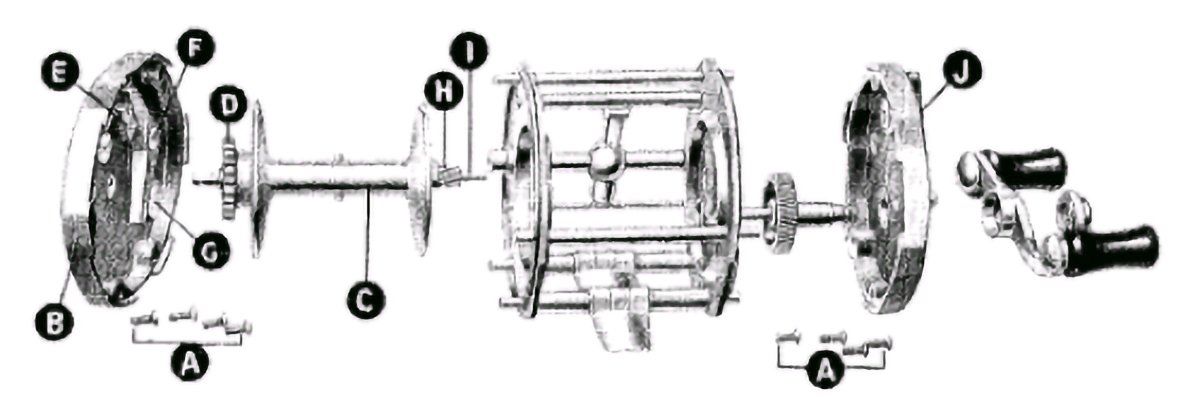

DISMANTLING

The reel should not be taken apart unnecessarily; once or twice during the season, for cleaning and oiling.

Dismantling of the level wind mechanism should be avoided unless it becomes absolutely necessary for cleaning or for the replacement of worn parts.

To dismantle the reel for cleaning the following procedure should be carefully observed.

FIRST see that CHECK and TENSION are "OFF", then:-

- Remove the four cover-fixing screws (A) from each cover (B & J).

- Lift off end covers.

- Withdraw line drum (C) While dismantled, and after cleaning, apply a little good quality light oil to the teeth of check wheel (D) and check pawl (E), and to the pivotal bearings of the check lever and cam (F and G).

ASSEMBLY

To re-assemble:

- Replace cover (J), and fixing screws.

- Replace line drum taking care that the gear pinion (H) is correctly fixed on the flats of the spindle (I).

- Replace cover (B), and fixing screws.

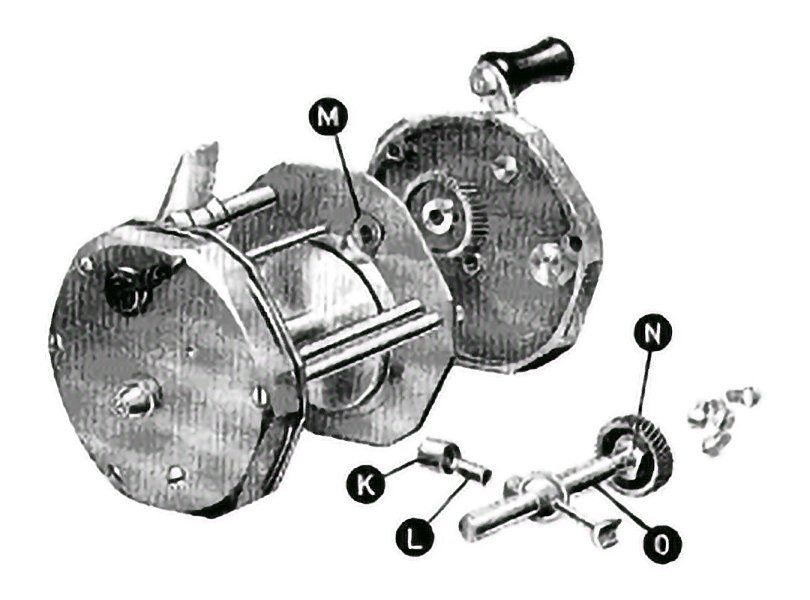

LEVEL WIND MECHANISM

Care should be taken when replacing level wind mechanism that the flats in the right-hand eccentric plate (M), fixing bearing (N) and sleeve (O) are properly engaged.

Replacing pawl with care as instructed above and retaining cap should be final operation.

This unit, although foolproof in function, may be susceptible to damage from grit getting into the double cross thread track in which a pivoting pawl is engaged and retained in position by a screwed cap.

Spare pawls are available if required, and to replace one worn or damaged, remove cap, extract old pawl and insert new one, taking care that the 'tongue' is properly engaged in the track before screwing on cap.

Should it be necessary to strip down this mechanism, first remove the cap (K) and pawl (L), remove end cover (J) as previously instructed, when the level wind mechanism can then be withdrawn, cleaned and replaced and the reel re- assembled.

DOUBLE PIVOTAL BEARINGS

The spindle ends of the line drum are housed in adjustable bearings located in the end covers. Each bearing is fitted with an adjustable set screw, providing fine adjustment for positioning the line drum symmetrically in the frame and for taking up excessive 'float' between the bearing points. These should be set so that the line drum is free without end play or 'float'. On no account must these set screws be tightened up for providing tension on the drum.

The cam-operated lever, conveniently placed for easy setting, provides a wide range of adjustment of the sensitive Drag according to the weight of the lure. Careful use of the Drag will assist in the prevention of over-running.

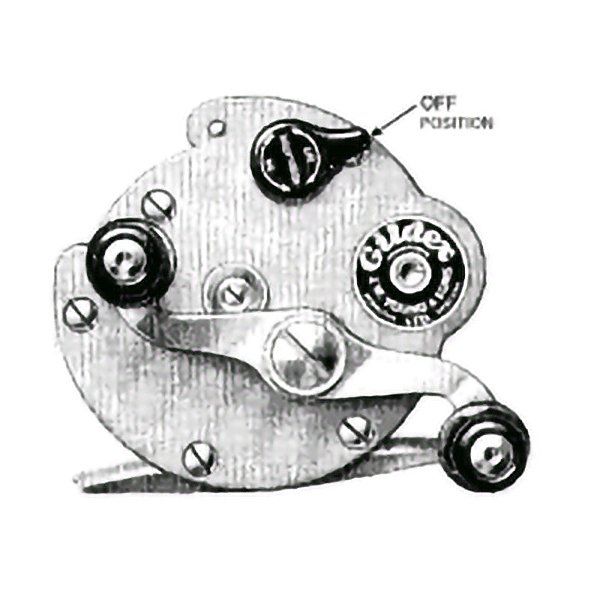

With the lever in the "OFF" position the drum is entirely free, and casting can be controlled by "thumbing" the line. The lever should be kept in the "OFF" position when not in use, thus avoiding fatigue and distortion of the spring.

NOTE: On all "GILDEX" models the drag regulating lever applies the required range of tension when revolved approximately one half turn anti-clockwise from the "OFF" position (see illustration). More than the half turn releases the tension.

HINGED ROD ANCHOR OR REEL SEAT

This is an entirely new feature providing permanent fixture to the reel without the common aid of screws or brazing. The pillars of the reel passing through the hinged bearing of the plate, ensure security without any possibility of coming adrift.

The movements of the swivel ends, which may be turned inwards for convenience of packing and prevention of damage, make the seat very adaptable and applicable to the variety of rod fittings used; the rigidity of the reel when fitted to the rod being unimpaired. The double taper ends are suitable for either trout or salmon rod fittings.